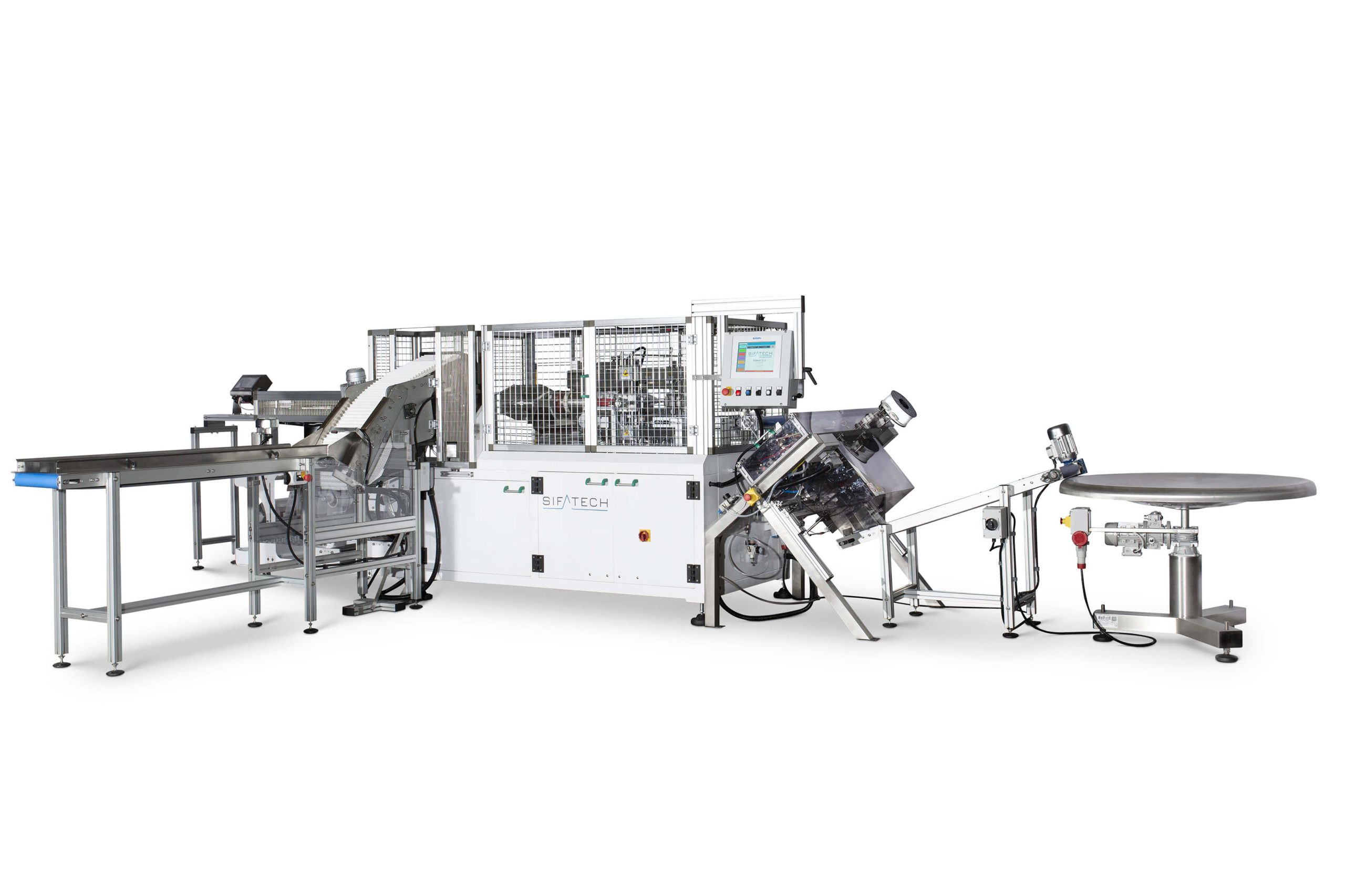

Horizontal packaging machine for breadsticks

The fully automatic dosing and packaging line has been designed to operate with a single operator loading the products to be packaged ‘Grissini Artigianali’.

This line will allow a better use of human resources within the plant, and a continuous control of the exact weight of the packages produced, thus eliminating the problem of overdoses due to manual loading without a continuous weight control.

The prerogative of the proposed system is to drastically reduce product breakage during the normal dosing and packaging phases.

Technical details

Maximum pack size: 450 x 250 mm

Maximum production: 15 packs/min.

Features

SUPPLY POWER

Power circuit: 380 V c.a. trifase+neutro+terra

Maximum production: 15 packs/min.

Command circuit: 24 V c.a.

Electrical power inputa: 2 kw

ENERGIA PNEUMATICA

General pressure: 6 bar

Air consumption (ntl-bar): 4 nl per cycle

Operation:

The operator (a single worker to run the line) loads the breadsticks, directly from the oven trays, onto the smooth loading belt with a length of 1700 mm; an automatic device will arrange the breadsticks neatly on the belt which will carry the product to the machine’s electronic dosers up to the previously set weight.

Once the weight has been reached, a drawer conveyor will bring the dose of breadsticks in front of the forming tube of the packaging machine while the loading belt will bring more breadsticks to the dosing unit that will prepare the dose for the next bag in order to have a continuous cycle.

A pusher will place the breadsticks in the pack previously sealed at the bottom and at this point the packer will close the pack and apply, at your choice, the Twist tie to have a tufted bag or a square bottom bag.

Once the tuft has been applied, the outlet ribbon will bring the finished bags to a rotary pulping table ready for boxing.

All along the line the breadsticks are handled without ever undergoing any manipulation that could alter their integrity in order to obtain packages without broken breadsticks inside.