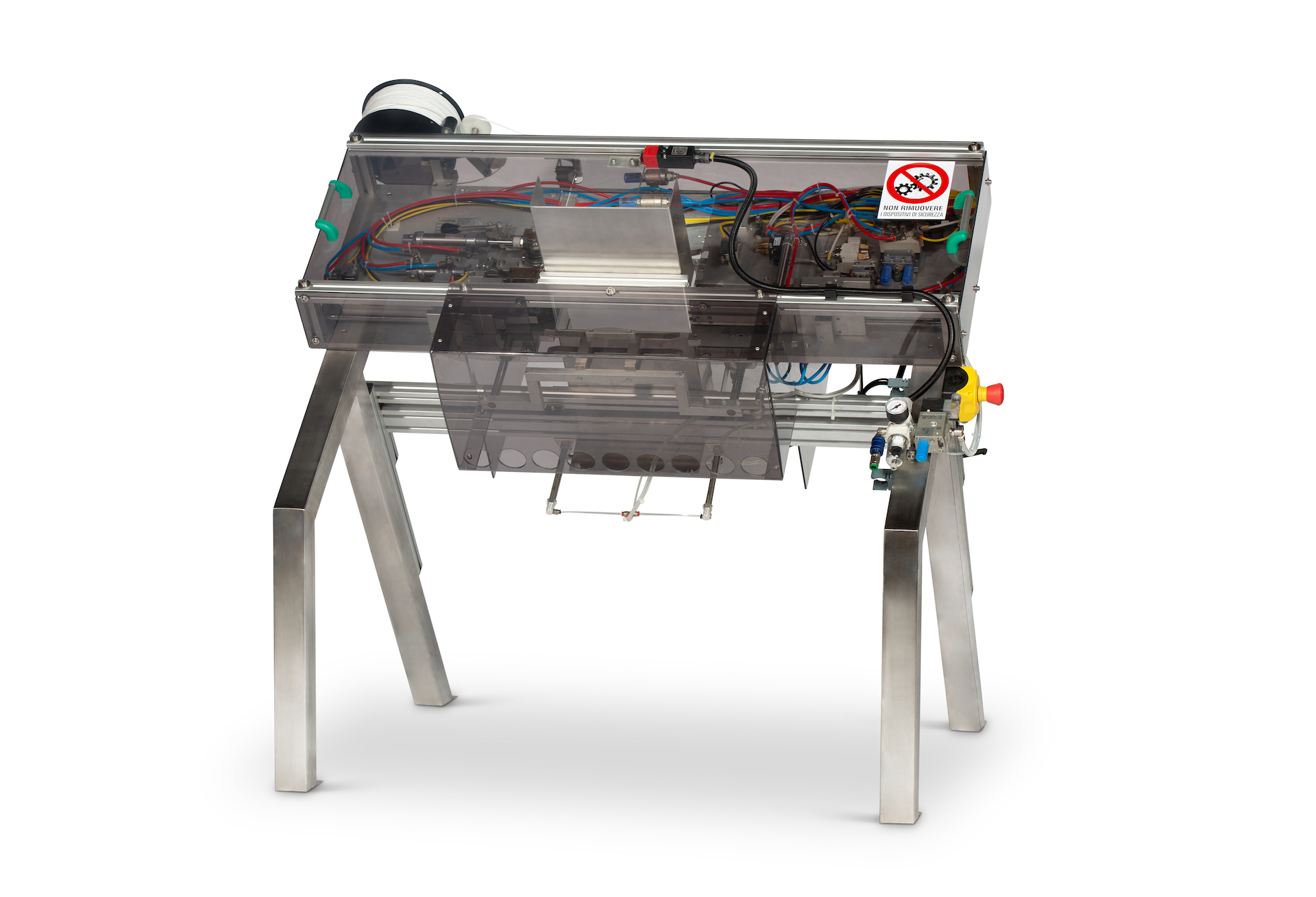

Automatic twisting device

Each line composed of:

1) Automatic twisting device on your tube packages of biscuits diam. mm. 90 coming from flowpack packaging machine and bag bottom ironing device.

The operation of the device supplied by us will follow the following process:

1) From the exit of your discharge chute, the package of biscuits will enter a load cell, the entry of which will be detected by a sensor/photocell. The load cell, with pneumatic movement, will turn the package into a vertical position.

2) When the package is in a vertical position, a blowing system will straighten the tuft of the bag.

3) The tuft of the package will be taken by the gripper n. 1, which will make a 180° rotation, after which the clamp will move the package to the mouth of the twister.

4) The twisting machine will apply the twist-band.

5) At the same time the caliper no. 2 will take the next bag.

6) In the next phase the caliper no. 1 will come out of the twister and start rotating, dropping the bag halfway into the discharge chute.

7) The cycle will continue alternating gripper no. 1 and caliper no. 2.

The system will have a load-bearing structure in anodized aluminium. The pneumatic parts will be SMC branded. The management of all operations of the device will be handled by a microprocessor.

Technical details

Production: Kg.150/hour – net kg.120/hour

Installed power: Kw 245 V 380 Three-phase

Compressed air consumption: 1000N/L 6 bar

Number of operators employed: 3

Ordinary maintenance: Daily cleaning

Extraordinary maintenance: Weekly deep cleaning

Scheduled maintenance: Quarterly technical review